easy40

A 14-components high-power transmitter to get you quickly on the air

please ask for KIT availability!

UPDATE 24-4-2020.

The above image shows more modifications. I have completely altered the

transformer to use air core and an additional winding essential for

tuning the transmitter when in the field. For the oldest version of the

transmitter, read this page below.

Introduction

QRP

is all about doing more with less. This is more than true, with the

construction of this cheap, small-size, keep-it-simple transmitter presented here. It

is just remarkable how 14 components can lead in so much output power,

that lets you commnicate with a big part of the globe, when propagation

conditions are right. From all my other constructions, this one stands

out in terms of simplicity in balance to the performance.

Following my instructions, the transmitter can be reproduced easily,

within hours. The result is always success, this is one of the circuits

that are not critical at all and a successfully working transmitter can

be reproduced every time. I have built this transmitter several times,

using similar components and it always worked. However the components

and the way of construction I present here, ensures stability and low

cost and guarantees that the transmitter will always meet the next

specifications:

Main carrier output power (excluding harmonics): 2.5mW-8W

(adjustable) at 50R

Band of operation: 40m

Output power adjustment: Vcc=2.5V for 2.5mW out, Vcc=29V for 8W out

Output impedance: 50R

Modulation:

CW (with external key), Feld-Hell (with external switching circuit) and AM (with external series modulation

transformer, or electronic series modulator)

Key operation: key breaks full transmitter DC

power

A little history

For years, I wanted to design a transmitter that would be very easy

and cheap for almost anyone to build, yet quite powerful. I have seen

hundrends of circuits on the net and on old magazines and very few come

as close as this one, when compared to simplicity and power output. Yet

not extremely stable especially when operating at high power, however

many contacts can be achieved with this tiny transmitter, more than

anything else of the same cost and components count I have seen.

I got the idea for this tiny transmitter, after reading an article written by AE6C on QST (1, 2, 3),

so I do not claim authenticity. However, even his idea, comes

from pre-WWW2 valve circuits, where components were big, bulky and

expensive, so saving some of them was worth it back then. The

article describes in detail the operation of such a circuit. However,

the maximum power output of the circuit in the article, was 2W. Where

I claim authenticity, are the modifications I made to the circuit to

boost the quality of the output signal, the stability and the output

power, as well as a completely different mechanical

approach. As radio amateurs, we ought to improve circuits to our

benefit!

The transmitter construction

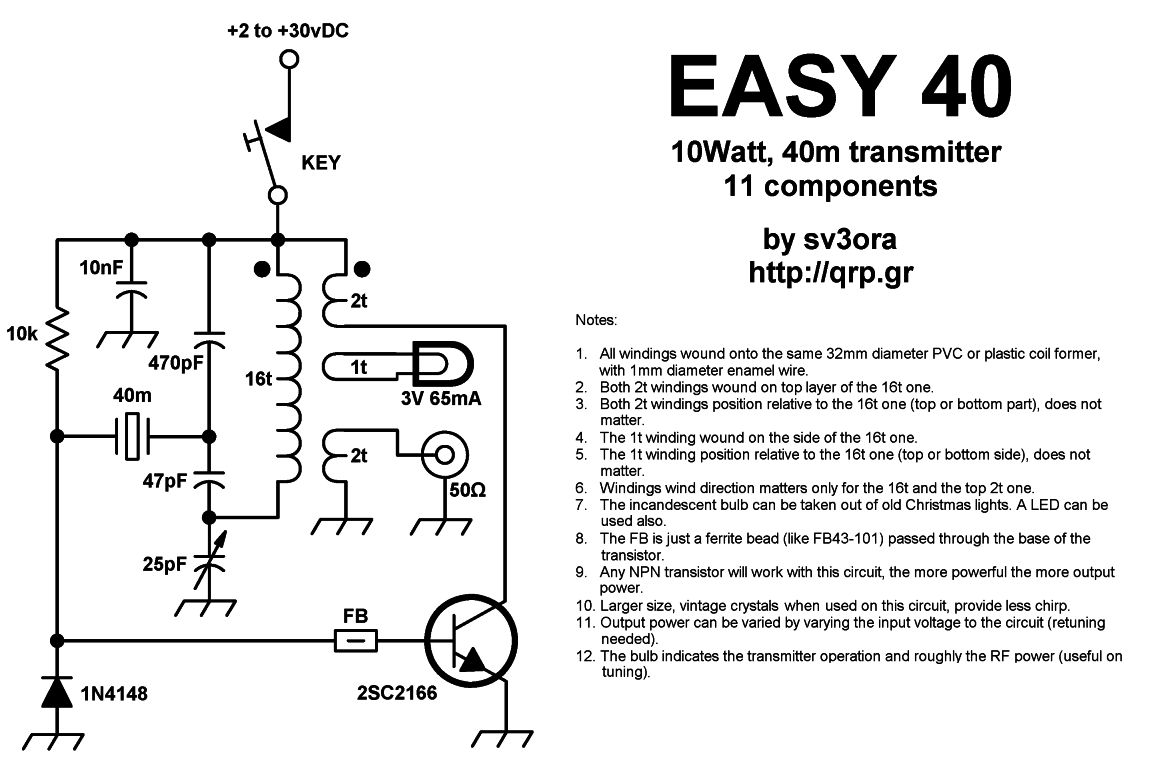

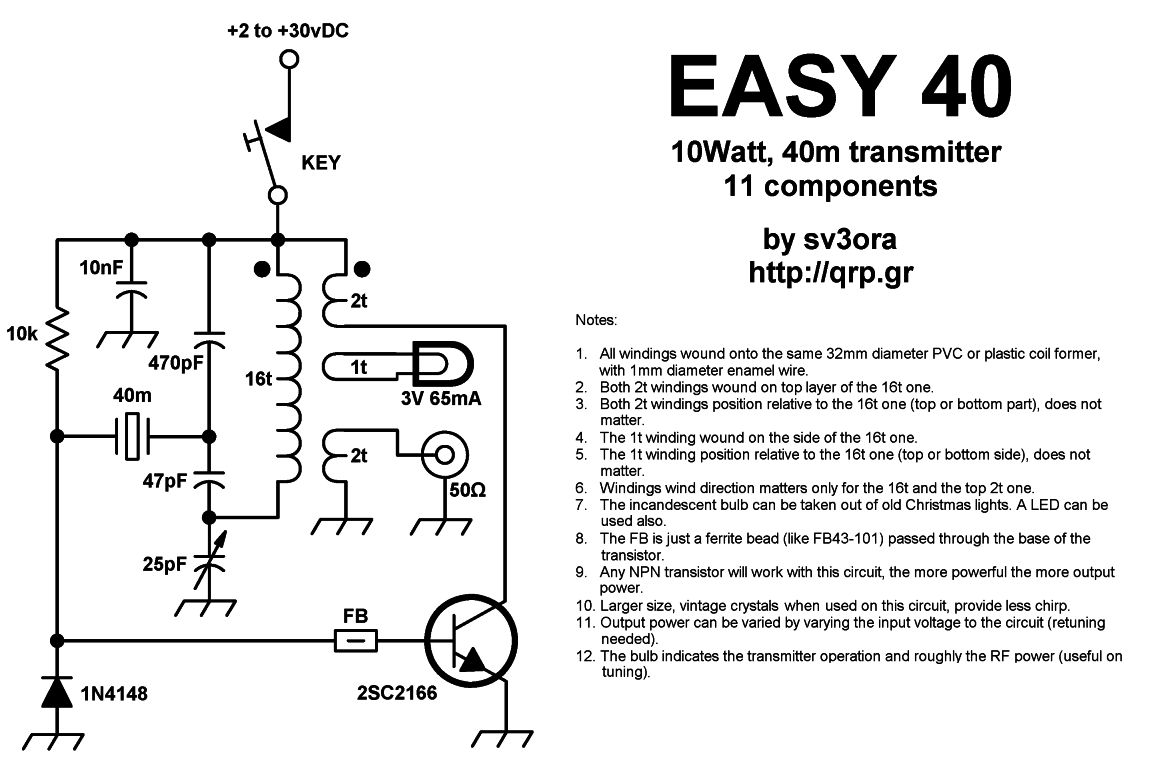

The

schematic of the transmitter is shown below.

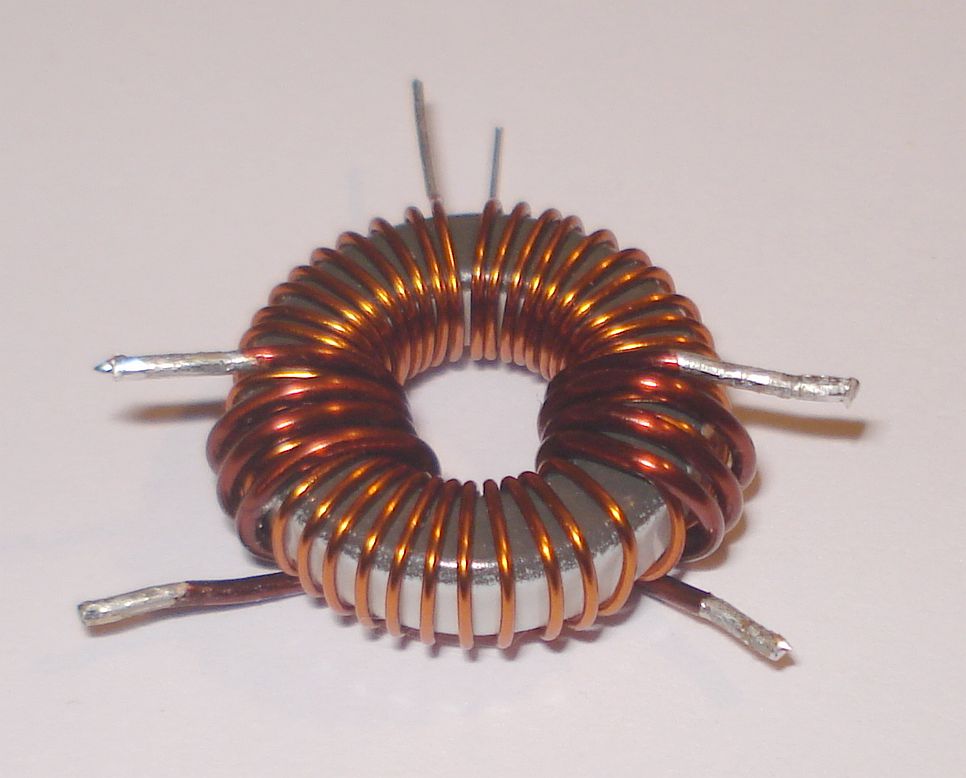

The inductor at the base of the transistor, is just an FB43-101 ferrite

bead, passed through the transistor base lead.

The output filter inductor L, is about 850nH. It is wound with 13 turns

of 1mm diameter enameled copper wire, evenly spaced, on an Amidon T68-7

toroidal core.

The transformer T, has three windings (T1, T2, T3) and it is made the

following way:

- Take a piece of 0.5mm diameter enameled copper wire and

wind 39 turns, evenly spaced, on an Amidon T68-7

toroidal core. This is the T1 winding.

- Then take a piece of 1mm diameter enameled

copper wire and wind 4 turns on one side of the same

toroidal core. These 4 turns are wound on the top layer of the 39 turns winding.

This is the T2 winding.

- Finally, take another piece of 1mm

diameter enameled copper wire and wind another 4 turns,

onto the same toroidal core. These additional 4 turns are also wound on

the top layer of the 39 turns winding, but on the opposite side of the core, than the previous 4

turns. This is the T3 winding.

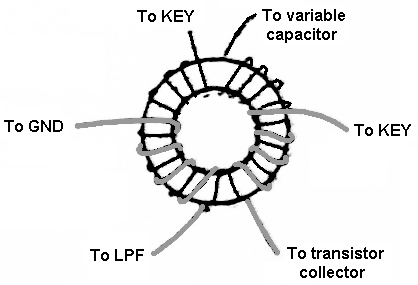

It is important to wind all three windings of the transformer in

the correct phase. That is, the beginnings and endings of the wires

must be wound exactly like shown in the picture below. For example, for

T1 winding, the wire must start from the KEY position and pass in front

of the

core (not hidden below it), then inside the core. The other end of the

T1 winding, should

then go to the variable capacitor, leaving the core from it's back side

(hidden below it). Each time the wire passes from inside the core, this

counts for one turn.

The picture

below, shows the finished transformer and the phasing (direction of

winding) of the wires can be clearly seen.

I

suggest you to use FT-243 crystals or older big crystals with this set.

The tiny modern crystals, while they do work, they produce much more

chirp (frequency drift when keyed) because they are heated much more

than the bigger older crystals.

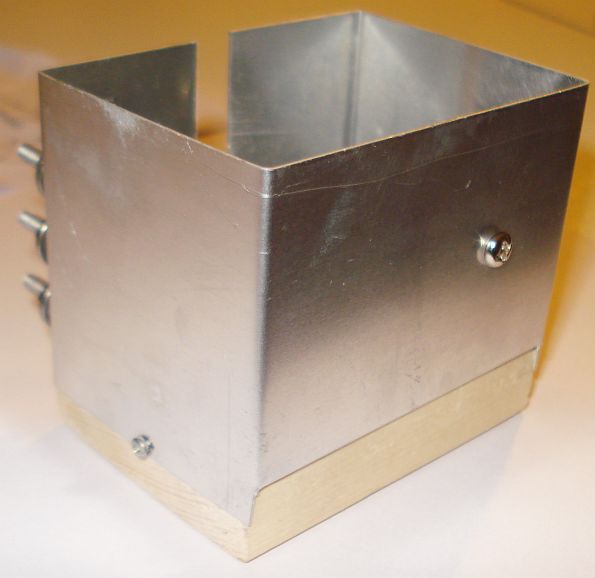

The

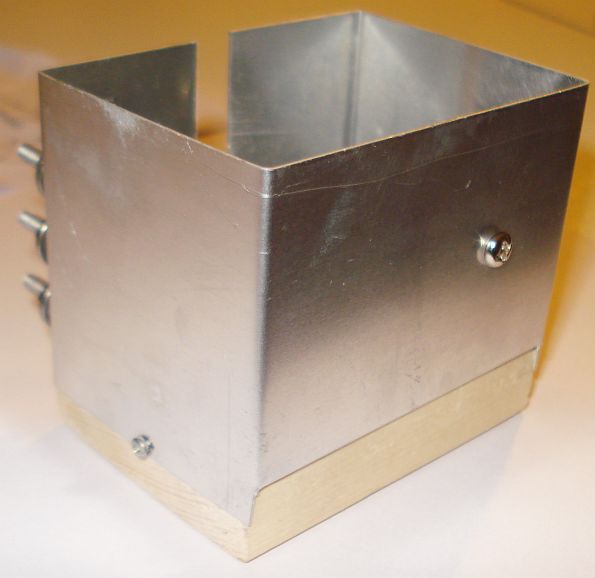

enclosure of the transmitter is purely homebrew. Not only it looks

better than the commercial enclorures, but it is also very cheap, easy

to build, lightweight, in the right dimentions and plays an important

role on both the mechanical and the electronic construction of the

circuit. It has been made using a wooden base (breadboard), which

holds the components using nails and metal walls that are made out of a

single thin

sheet of aluminium, cut and bent to the right shape. The

aluminium sheet is thin enough, so that it can be easily cut using a

pair of scissors and bent using finger pressure and a ruller.

The aluminium walls, host the connectors for the transmitter, but they

are also used as a heatsink for the transistor, eliminating the need

for a separate heavy, bulky and usually expensive heatsink. The tests

have

shown that even this thin sheet of aluminium, can easily take the heat

apart from the transistor, even at high power levels and prolonged

transmitting times. Note that in this transmitter, it is best to

electrically insulate the aluminium heatsink from the components, so a

piece of mika thermoconductive insulator was used in conjunction with

plastic-ring screw insulator, to attach the transistor to the heat

sink. Thermoconductive paste, is absolutely not necessary to be used,

althought it is not a bad idea to use it if you have it on hand.

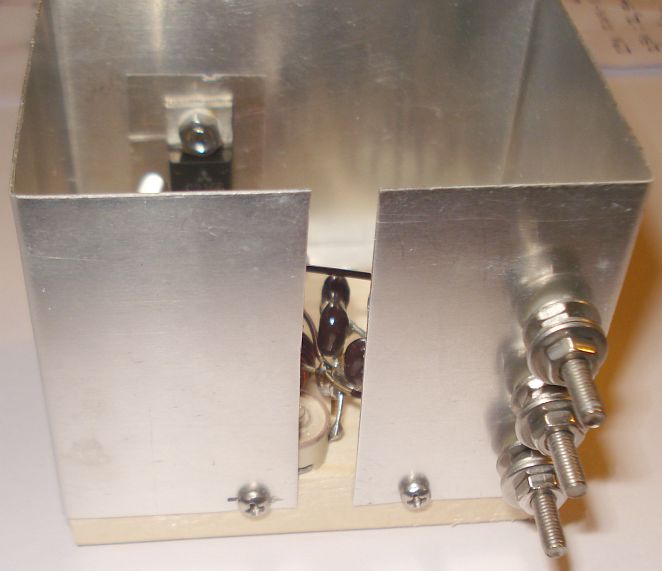

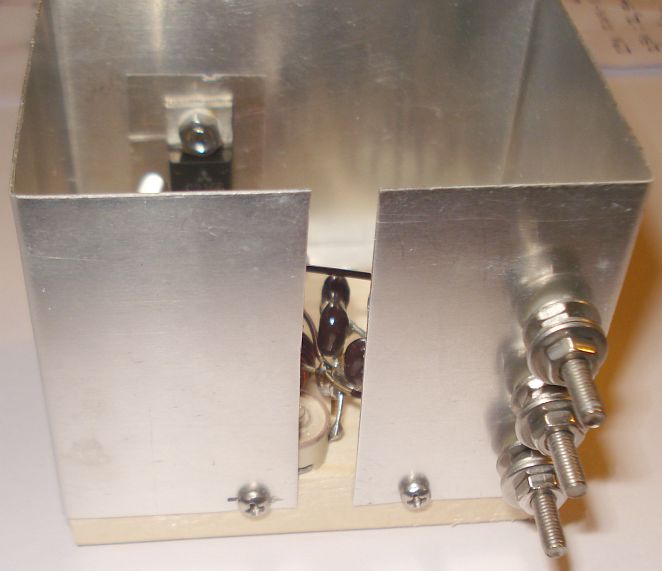

Since

one of the goals was to make a cheap transmitter for the field,

expensive connectors are not used. For the power and the antenna

connections, ordinary cheap (but high durability) stainless steel

screws, nuts and bolts were used, to create the

connectors. The screws are larger in length, to allow both crocodile

clips and bare wires (using locking nuts and bolts) to be easily

attached. This solution is highly durable (large number of connection

cycles) but more importantly it is cheap and very convenient in the

field, where suitable coaxial connectors are not always available and

there is a high risk to forget taking compnents with you.

However if using it with coaxial cable from inside the shack, you may

want to make yourself (or buy) a wire-to-coaxial adaptor, to avoid RF

leakage in the shack. The output of the transmitter is 50 ohms, so you

would need no matching to the coaxial cable. Most possibly, your

antenna would need matching to 50 ohms at HF, not your transmitter.

Just as in the transistor case, the screws of the connectors (even the ground) must be

isolated from the aluminium heatsink, to minimize hand effects and

ensure stable operation. For insulators, a few pieces of transistor

insulating plastic rings were used.

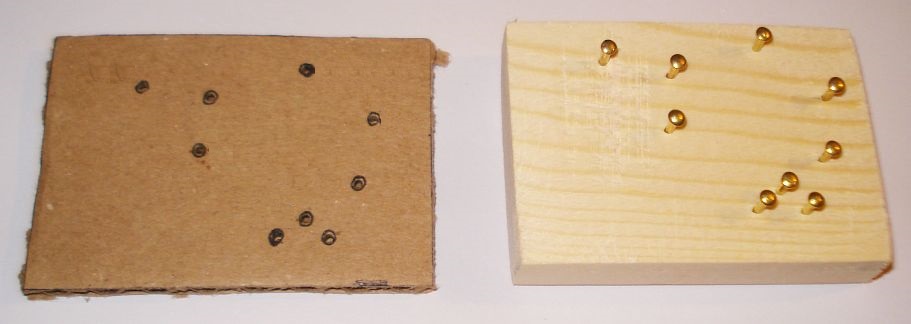

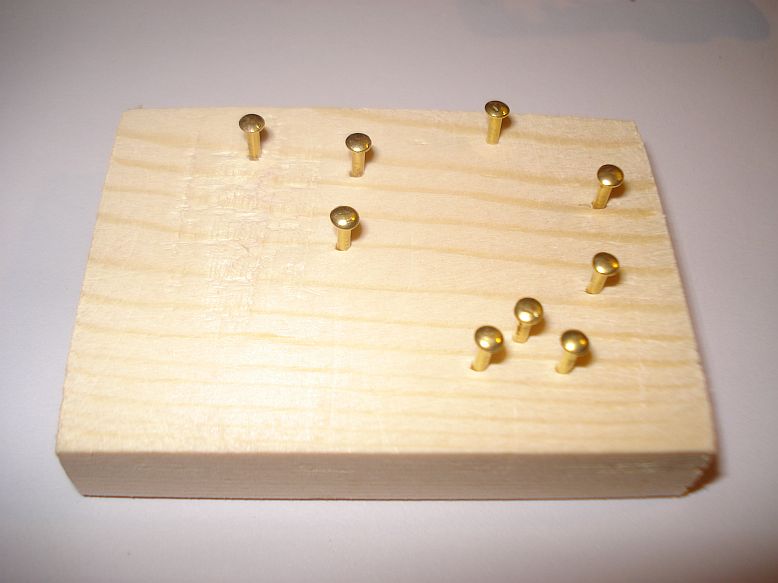

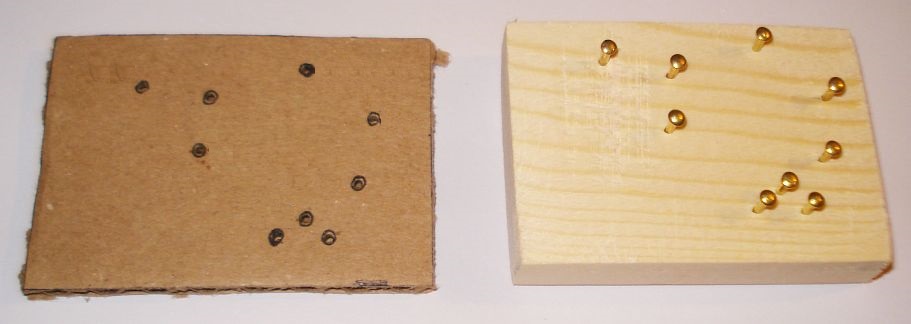

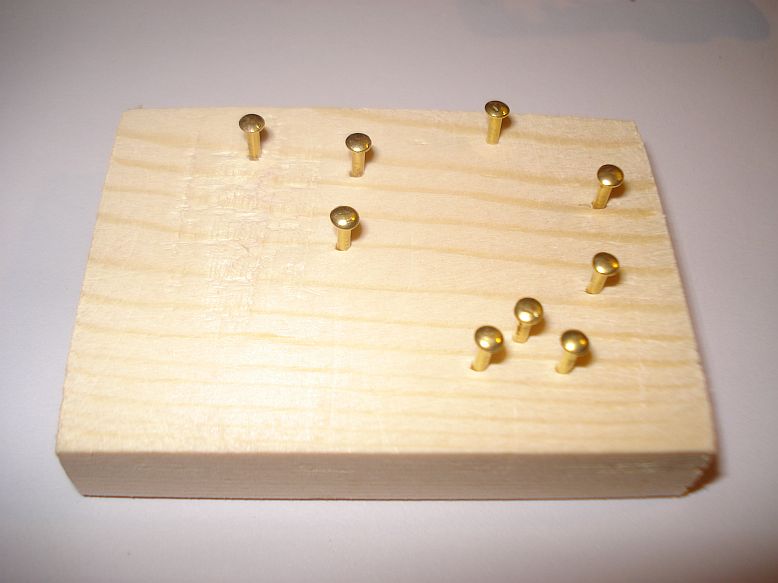

The

circuit is made in breadboard-style onto a piece of wooden base, cut in

the right dimensions, which also serves as an electrical and thermal

insulation between components. Nine solderable nails, nailed onto the

wooden base, serve for the mechanical stability of the components and

help solder the components leads together.

The nails positions are not arbitrary. They are placed like this, to

achieve minimum connection lengths between components and avoid the use

of extra wiring. To make it easier for you to place the nails, I have

created a template. Simply put the template onto the wooden base and

nail the nails onto the wood, at the predefined positions.

The

next pictures, show all the components of the transmitter, soldered

onto the wooden base nails. This construction may look ugly, but from

the RF point of view it is optimal, since the connections between

components are minimized.

Since

the output power of the transmitter can be varied by varying Vcc, the

transmitter can be easily AM modulated, by replacing the key with a

series connected transformer, as shown in the schematic below.

I have

tested this configuration with a small series transformer, taken out of an old TV

speaker, which has a primary of 4 ohms (audio amplifier side) and a

secondary of 120 ohms (transmitter side).

To drive this transformer, a TDA7360

integrated amplifier, working in bridged mode and driving the 4 ohms

primary directly, thought to be a simple way. Indeed this class-AB

amplifier combined with the transformer modulator, form an efficient AM

modulator. If efficiency is the goal, this is the way to go. However,

this approach requires three additional components for the modulation.

A suitable audio transformer (which is not always available and easy to

find), an amplifier IC and a separate PSU for this amplifier (TDA7360

works on 18V max).

If

efficiency can be sacrificed though, AM modulation can be achieved with

a series BJT or FET in place of the transformer. Similarly, an LM317

can be used and this can double it's use as an AM modulator as well as

a variable PSU for the transmitter (to vary the output power of the

unmodulated carrier). Since the goal of this transmitter is simplicity,

this can be an acceptable way.

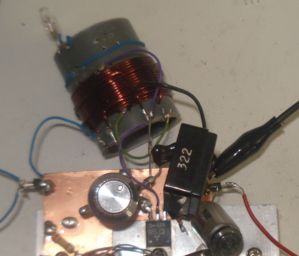

I

have even tried to make a coreless transformer for this transmitter. It

worked but it produced much mess power. However, I did not have the

time to optimize the turns ratio, but at least I got the phasing of the

windings correct. Anyway, here is the construction of the coreless

transformer for anyone interested.

Back to main site